Durable EPDM Rubber Sheet

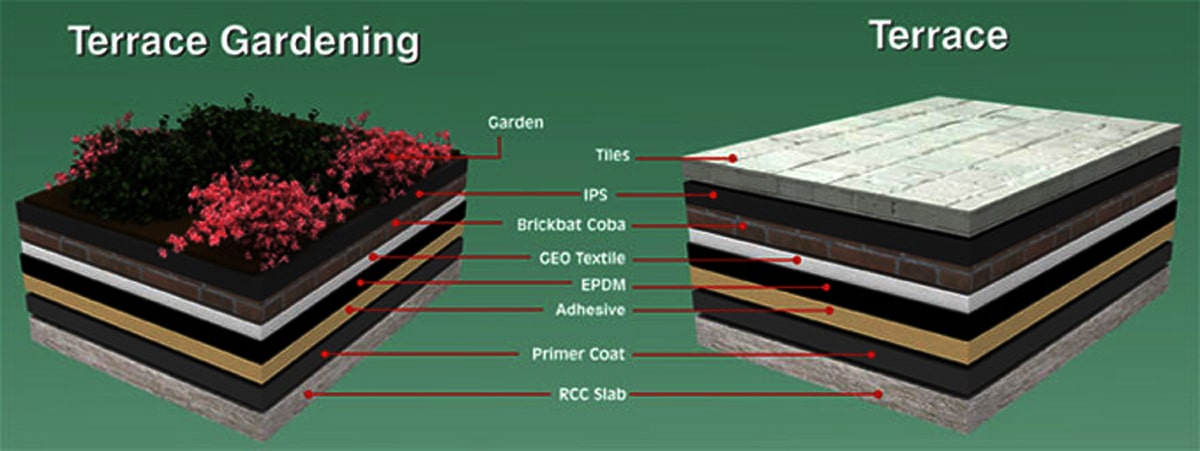

This reliable waterproofing is essential to every building as this membrane never allows water to pass through and maintains this amazing quality over years. It withstands movements of the structure, bad weather, chemical degradation and mechanical stress and strain.

Moreover EPDM (ETHYLENE PROPLEYNE DYMER) membranes are economical solution compared to traditional systems, not a single drop of water will pass through the EPDM membrane.

Moreover EPDM roof membranes are economical solution compared to traditional systems, not a single drop of water will pass through the EPDM membrane roof. EPDM Rubber Sheet can withstand temperature from -40ºC .EPDM Rubber can be stretched to 400%; the membrane will not tear, crack to +140ºC or split. It has an unfailing flexibility.

Durability

EDM Rubber Application is warranted for 10 yrs. This does not imply that it is durable only for this period. The treatment, being very inert, is durable for a very long period.

Technical Specification of EPDM Rubber Sheet :

EDM Rubber Application is warranted for 10 yrs. This does not imply that it is durable only for this period. The treatment, being very inert, is durable for a very long period.| Property (Metric SI Units) | Test Method | Specification | Properties |

| Tolerence on nominal thickness % | ASTMD 412 | +10 | +10 |

| Colour | Black | ||

| Tensile strength, min. Mpa | ASTMD 412 | 9.0 | 11.2 |

| Elongation , ultimate , min % | ASTM D 412 | 350 | 520 |

| Tear resistance , min , kN/m | ASTMD 624 (DIE C) | 30.6 | 40.3 |

| Resistance to heat aging* | ASTM D 573 | ||

| Properties after 4 week @ 115˚c | |||

| Tensile strength , min, Mpa | ASTM D 412 | 8.3 | 11.0 |

| Elongation , ultimate, min. Mpa | ASTM D 624 | 225 | 310 |

| Taer resistance , min. kN/m | ASTM D 624 | 26.3 | 42.0 |

| Linear dimensional change . max % | ASTM 1204 | +20 | -0.4 |

| Ozone resistance | ASTM D 1149 | No cracks | No cracks |

| Condition after exposure to 100 pphm | |||

| Ozone in air for 168 hours @ 40˚c | |||

| Specimen @ 50% strain | |||

| Brittleness temp max ˚C | ASTM D 746 | -59 | -65 |

| Resistance to water absorption | ASTM 471 | ||

| After 7 days immersion @ 70˚C | 4.0 | 2.0 | |

| Resistance to outdoor (ultra violet) weathering* | ASTM G 26 | No cracks | No cracks |

| Xenon arc , 4000 hours exposure, 80˚C | No crazing | No crazing | |

| PSI | 10 Kg/mm | 11Kg/mm |

-

01 What is an EPDM rubber sheet?

EPDM rubber sheet is a durable, weatherproof material used in roofing, ponds, and various sealing applications due to its flexibility.

-

02 What is EPDM rubber used for?

EPDM rubber is used for roofing, automotive seals, gaskets, electrical insulation, and waterproofing due to its durability and resistance to weathering, UV radiation, and temperature extremes.

-

03 Is EPDM rubber waterproof?

Yes, EPDM rubber is waterproof. Its inherent properties make it highly resistant to water, making it suitable for various waterproofing applications such as roofing membranes, pond liners, and seals for doors and windows.

-

04 How long will EPDM last?

EPDM rubber is known for its durability and longevity, with a typical lifespan of 30 to 50 years or more when properly installed and maintained. Factors such as exposure to weathering, UV radiation, and other environmental conditions can affect its lifespan, but with proper care, EPDM can provide reliable performance for several decades.